NOVI, MICHIGAN — The key to building supply chain resilience may be as simple as using fewer parts to build a finished product, according to Lucid Motors VP of Engineering James Hawkins.

“Doing more with less is efficiency,” Hawkins said during a presentation at AutoTech 2025. “Doing more with less is at the heart of sustainability and at the heart of resilience.”

When designers and engineers were in the initial stages of creating Lucid’s first battery electric vehicles, the company considered the needs of potential buyers, including performance, range and passenger comfort.

The challenge wasn’t determining what had to go, but how to deliver everything, Hawkins said.

These traits set the baseline for designing vehicles that not only met perceived consumer expectations, but could also be produced domestically with minimal dependence on components made overseas.

An initial step was to construct a 1 million square-foot factory in Casa Grande, Arizona, in 2021, Hawkins said. The plant has since expanded and now boasts 3.9 million square feet of production space, where the company stamps its own body panels and builds vehicles.

With production capacity ensured, the company’s next focus was securing domestic suppliers. The EV maker recently inked a battery materials deal with Graphite One. It will also procure U.S.-made batteries from Panasonic, Hawkins said.

The volatility in the global marketplace, fueled by the Trump administration’s tsunami of tariffs, has prioritized domestic sourcing at Lucid.

“The automotive industry has felt an intense and acute vulnerability just this year,” Hawkins said. “Our response is actually a continuation of our existing strategy, and that is forging partnerships with our supply base for long-term domestic supply, wherever it strategically makes sense.”

While Hawkins stressed the importance of procuring as many U.S.-made components as possible, he added that if a finished vehicle had fewer components, it would both resolve potential supply chain issues and aid the company in developing a more spacious passenger cabin.

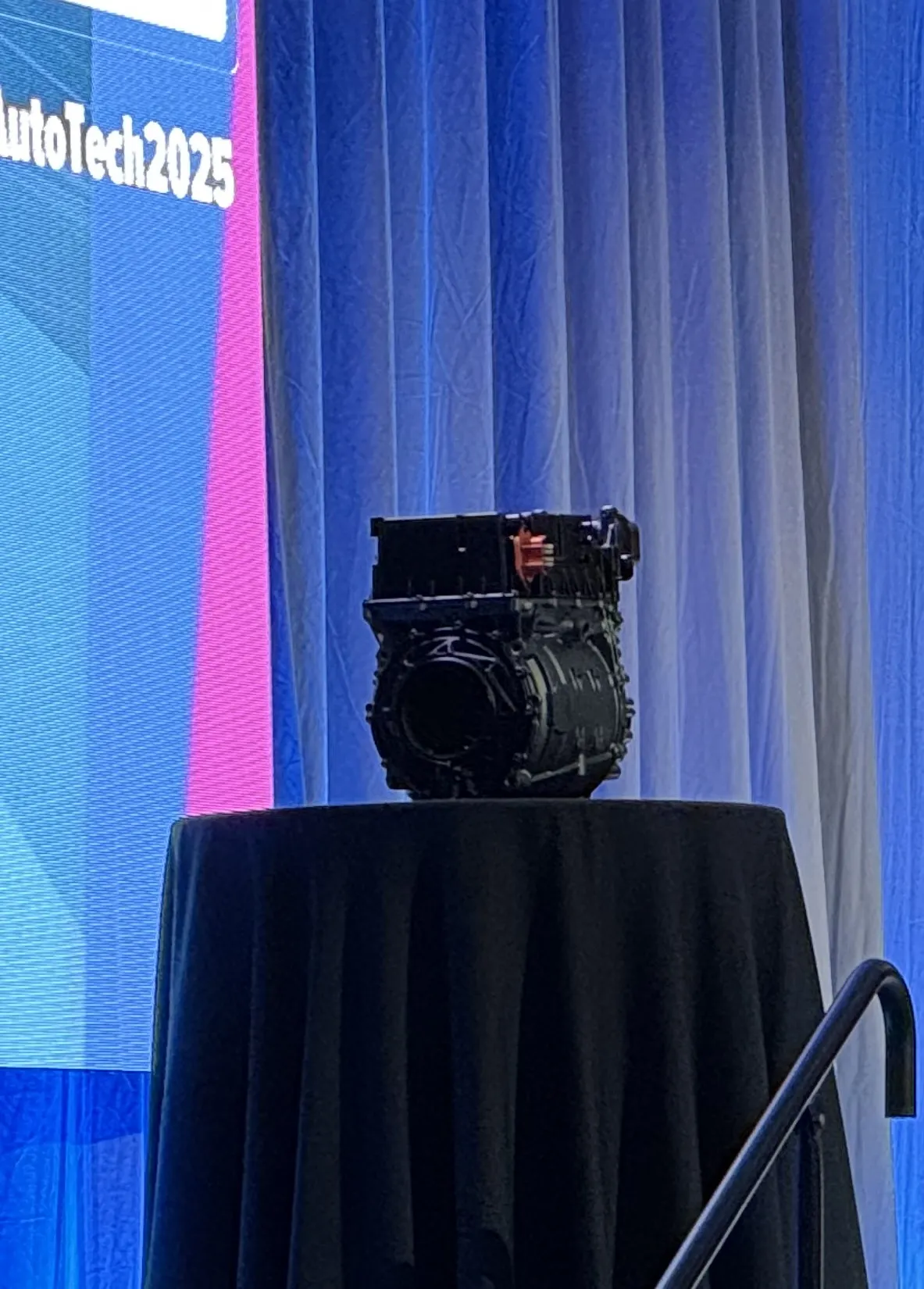

Pausing from his presentation, Hawkins retrieved a Lucid electric motor casing from a carry-on suit case. The motor casing is comparable in size to a small kitchen appliance, but when filled with its internal components capable of propelling a full-sized electric vehicle.

Miniaturization of vehicle elements means designers could configure roomier passenger spaces as well as a larger trunk area.

“This is a really obvious example of how we can do more with less,” Hawkins said.

In developing its base powertrain, Hawkins said the approach was creating something that could deliver more power, but with fewer parts to reduce costs and eliminate the need to outsource or make additional components.

“There’s fewer materials to source, process, deal with the end of life, recycle. Less mass engages in the benevolent cycle of efficiency,” he said.

Always seeking opportunities to operate efficiently is a mindset that resonates throughout Lucid, Hawkins said.

“I think what this year has taught us, if nothing else, is that we need to be continuously understanding and evaluating what resiliency means, what the risks to our companies are, [and] what our strategies should be in response,” he said. “Absolutely, it needs to be continuously and thoroughly examined to make sure that we’re covering our bases.”

Disclosure: AutoTech2025 is run by Informa, which owns a controlling stake in Informa TechTarget, the publisher behind Automotive Dive. Informa has no influence over Automotive Dive’s coverage.